Who would have thought? I'm still managing to get some e-boarding miles in the winter here in the UK! These last couple of months I haven't had much chance to e-board because the ground has always been wet (The resulting sprayed mud on the work trousers is not a good look). But today was brilliant - the weather forecast was spot-on and there was no rain.

Here's an image of my board at the bicycle shed after commuting to work. I will have to see how many more commutes I can squeeze in before the weather completely stops me. It is getting harder to e-board on the return journey given that it gets dark from 16:30 onwards.....(much harder to see all the pot holes!).....

Wednesday 8 November 2017

Tuesday 15 August 2017

Who would have thought there would be so much to know about wheels

What I've noticed now is that due to the rough roads I have been travelling on during the commute to work, my wheels (particularly the one connected to the motor) are starting to look a bit chewed up. So, like with a car, I am going to regularly swap the wheels around (back to front) to equalise the wear on all wheels.

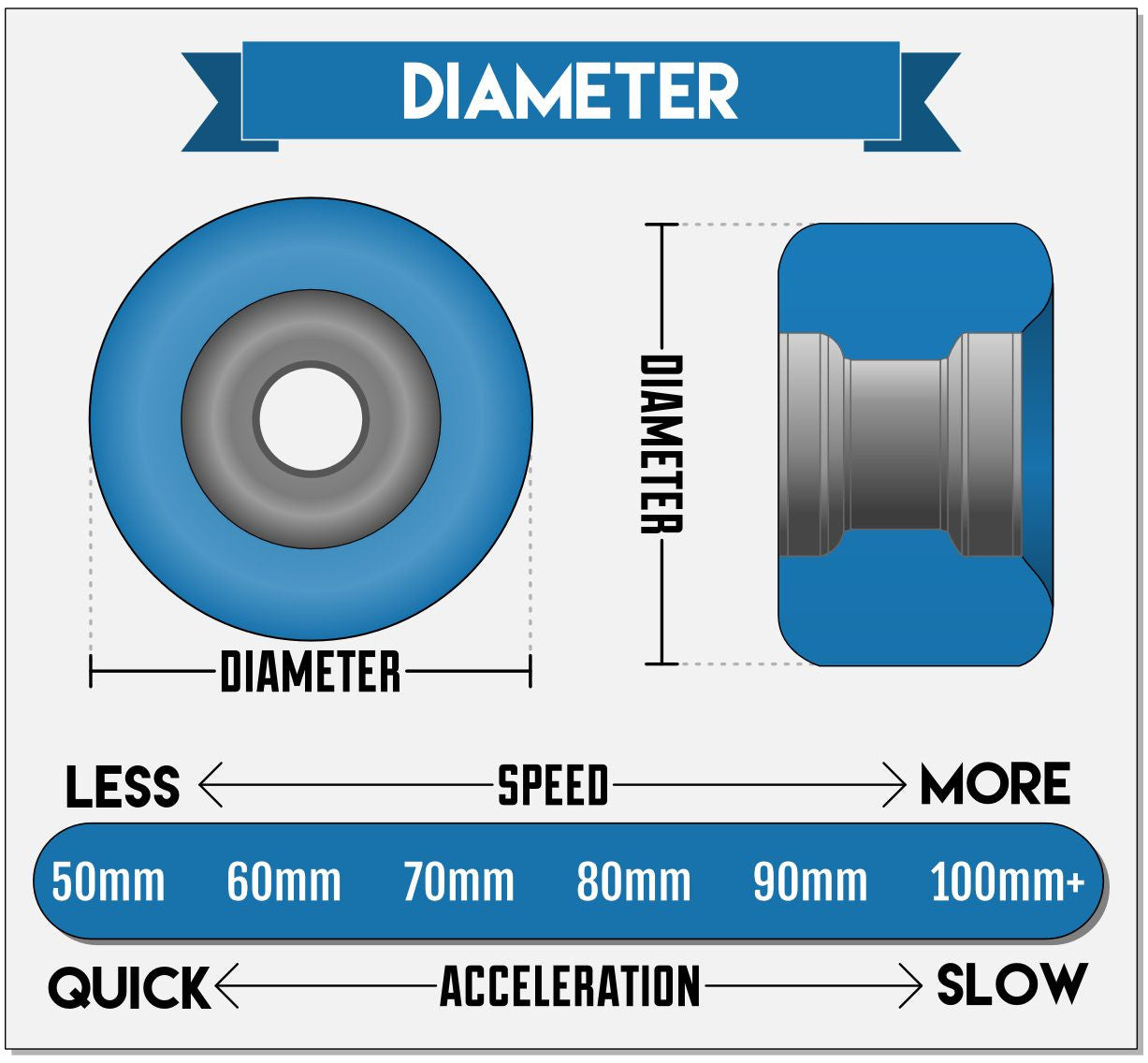

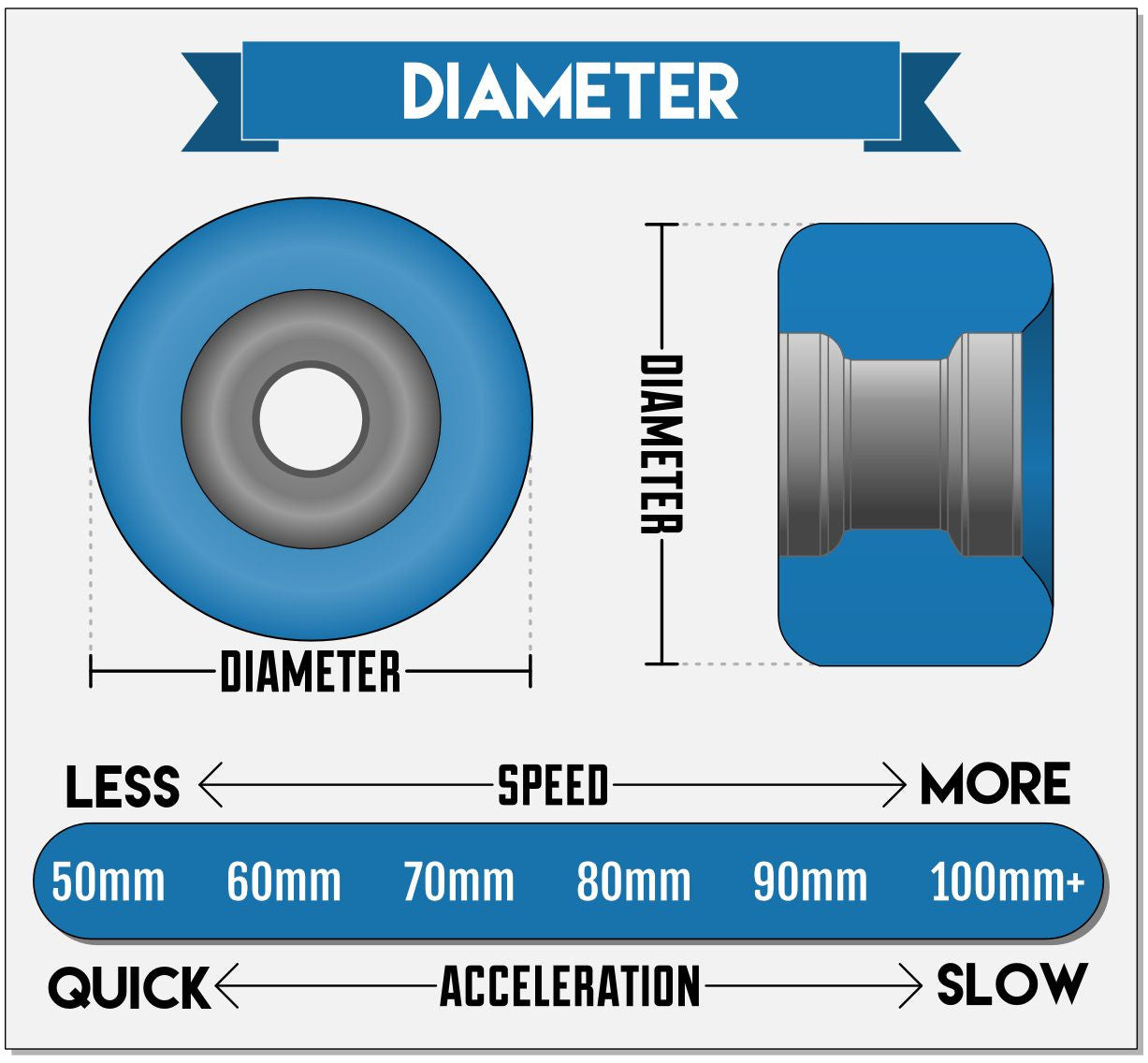

I often have thought about changing the wheels on my board. Larger diameter ones would make it go faster, smaller ones give it better torque going up a hill. Stoked LA give a very good overview about wheels for your long board.

It seems the 78A PU 90mm wheels that come as standard on my Volo-e longboard are a safe bet. Though, interestingly Stoked LA advise that going over 80mm diameter can give risk of bending the standard 8mm axles of a skateboard truck with aggressive riding (but I think that is more to do with non electric boards)

Stoked LA present all aspects of wheels that should be considered by a skateboarder: diameter, width, durometer wheel lips etc. Who would have thought there would be so much to know about wheels?

I often have thought about changing the wheels on my board. Larger diameter ones would make it go faster, smaller ones give it better torque going up a hill. Stoked LA give a very good overview about wheels for your long board.

It seems the 78A PU 90mm wheels that come as standard on my Volo-e longboard are a safe bet. Though, interestingly Stoked LA advise that going over 80mm diameter can give risk of bending the standard 8mm axles of a skateboard truck with aggressive riding (but I think that is more to do with non electric boards)

Stoked LA present all aspects of wheels that should be considered by a skateboarder: diameter, width, durometer wheel lips etc. Who would have thought there would be so much to know about wheels?

Monday 17 July 2017

Tactile paving - The bane of any electric skate boarder's life

Tactile paving they call it, and its there to warn pedestrians with visual impairment that they have reached the edge of the pavement. This paving comprises small round bumps and boy they sure vibrate your board and body as you ride over them.

Now, with the weather being more sunny than rainy these weeks (yes despite that statement I still live in Wales), I've been using the board a lot more to get to work. However, there have been two recent and unfortunate incidents as a result of riding over these bumps. First my speedometer stopped working and then a couple of weeks later my board suddenly stopped working. I will discuss in later blog entries about my fixes. But basically upon investigation, both problems were due to a solder connection between wire and electronic circuit board breaking off.

This tactile paving is scattered around various parts of the urban landscape. But in the newly built train station by my work place they seem to have gone overboard, with a total of eight tactile pavings to negotiate in the space of three minutes.

The multitude of these tactile pavings is rather akin to the test tracks that auto-mobile manufacturers use to test their new vehicles:- They make different road surfaces present to intentionally "exercise" the car.

I'm sure every time I skate over these humps I am subjecting my poor board to an equivalent of five years extra wear and tear.

The design of the sloping pavement kerb means its not possible to skate to the left or right hand side of the tactile paving. This is highly annoying, as avoiding the tactile paving means travelling a further distance to bypass these tactile paved areas. Grrr.....

Now, with the weather being more sunny than rainy these weeks (yes despite that statement I still live in Wales), I've been using the board a lot more to get to work. However, there have been two recent and unfortunate incidents as a result of riding over these bumps. First my speedometer stopped working and then a couple of weeks later my board suddenly stopped working. I will discuss in later blog entries about my fixes. But basically upon investigation, both problems were due to a solder connection between wire and electronic circuit board breaking off.

This tactile paving is scattered around various parts of the urban landscape. But in the newly built train station by my work place they seem to have gone overboard, with a total of eight tactile pavings to negotiate in the space of three minutes.

The multitude of these tactile pavings is rather akin to the test tracks that auto-mobile manufacturers use to test their new vehicles:- They make different road surfaces present to intentionally "exercise" the car.

I'm sure every time I skate over these humps I am subjecting my poor board to an equivalent of five years extra wear and tear.

The design of the sloping pavement kerb means its not possible to skate to the left or right hand side of the tactile paving. This is highly annoying, as avoiding the tactile paving means travelling a further distance to bypass these tactile paved areas. Grrr.....

Monday 8 May 2017

Comparing electric skateboards

There's a guy over at esk8 forum who has kindly compiled a list of all known electric skateboards together with their various parameters. Even my Volo-E longboard is listed and doesn't compare too badly against some of the more expensive boards. The Google doc has all the board's specs and is ideal for anyone new to electric boarding. See the document here.

Tuesday 25 April 2017

Sunday 23 April 2017

Skateboarding gang!!!

Wife captured this on her walk into town.

They can only join my gang if they go electric :)

Sunday 12 March 2017

As mentioned in the previous post, this weekend was the first serious time on my board since September last year. This was the first proper test for robustness of the re-purposed bike computer I have documented in previous posts.

It did work most of the time but during one of the trips there was momentarily loss of the screen display when I mounted a curb. However, a few more bumps from the road, and the real time display showing speed and distance covered was working again.

I suspected that the battery for the bike computer was not as secure as it could have been and depending on the vibration from the road, sharp knocks would sometimes cause the battery to separate from the battery contacts. What I've done now is put "blu-tack" on the battery and between the lid of the housing to try and dampen out any vibrations causing battery movement. It seems to have done the trick.

Removing the cover

Adding blu-tack to secure the battery

Screwing the case housing back onto the underside of the board

It did work most of the time but during one of the trips there was momentarily loss of the screen display when I mounted a curb. However, a few more bumps from the road, and the real time display showing speed and distance covered was working again.

I suspected that the battery for the bike computer was not as secure as it could have been and depending on the vibration from the road, sharp knocks would sometimes cause the battery to separate from the battery contacts. What I've done now is put "blu-tack" on the battery and between the lid of the housing to try and dampen out any vibrations causing battery movement. It seems to have done the trick.

Removing the cover

Adding blu-tack to secure the battery

Screwing the case housing back onto the underside of the board

Spring is here!!!

So with Spring fully in progress, this weekend I was able to enjoy the dry weather and take my board on a night ride and a 3.5 mile daytime ride in the park. And oh what nice scenes greeted me:

Not having been on a long trip on the board for a while, I had forgotten how vocal the British public are. Not sure if it was because I was in the park and there were more people present than usual, but I heard four cries of "hey, that's an electric skateboard", or similar words to that effect.

Not having been on a long trip on the board for a while, I had forgotten how vocal the British public are. Not sure if it was because I was in the park and there were more people present than usual, but I heard four cries of "hey, that's an electric skateboard", or similar words to that effect.

Sunday 12 February 2017

Skateboarding in the UK

The biggest downside of commuting on an electric longboard in the UK is the rain and resulting puddles. My board manufacturer not only states that it is dangerous to skate in the rain but also that the electronics are at risk of being damaged.

Typically, I wake up and look out of the window to see if the roads are wet and if they are I forget about any idea of travelling on my long-board. However, I've been caught out a couple of times travelling to work on my board. For those occasions there hadn't been any rain on the day but it had been raining in the very early hours of the morning. The streets from my house would look pretty dry. I would then elect to travel on my trusty long-board and beeline to the park which forms the majority of my long-board commute to the train station. But upon entering the park I would discover the path had not dried off due to the wind shield from the numerous surrounding trees. The result: when I got to the train station, my trousers from ankle to knees would be covered in brown speckled mud. Goodness knows what my fellow passengers would have been thinking.

As a result my board has mostly been hibernating because of the weather this winter. Instead of road surfing I am forced to surf on the internet to get my long-board fix. As such, a recent discovery for me is that you can get mud guards for skateboards!

The supplier/manufacturer called Wheelshields (no longer online) is an American company and you can buy them for under 100USD (around £80 pounds at the time of writing). Interestingly, the shields are mounted on the outside of the wheel using the wheel nut to secure them.

The shields are reported as definitely working with boards that have wheels of 76 mm in diameter and under. But also wheels as large as 80 mm can also be accommodated depending on the board.

The manufacturer reports additional advantages of using their wheel shields other than just for splash protection. This includes eliminating wheel bite and increasing bearing life. A review of the wheel sheilds by 14Degrees (no longer online) claims these are a positive game changer.

Alas, the manufacturer will not get my immediate request for purchase as my wheels are 90mm in diameter. I have sent them an email to enquire if they make a solution for bigger wheels. In the mean time it's given me an idea to try and make my own guards. Watch this space :)

Typically, I wake up and look out of the window to see if the roads are wet and if they are I forget about any idea of travelling on my long-board. However, I've been caught out a couple of times travelling to work on my board. For those occasions there hadn't been any rain on the day but it had been raining in the very early hours of the morning. The streets from my house would look pretty dry. I would then elect to travel on my trusty long-board and beeline to the park which forms the majority of my long-board commute to the train station. But upon entering the park I would discover the path had not dried off due to the wind shield from the numerous surrounding trees. The result: when I got to the train station, my trousers from ankle to knees would be covered in brown speckled mud. Goodness knows what my fellow passengers would have been thinking.

As a result my board has mostly been hibernating because of the weather this winter. Instead of road surfing I am forced to surf on the internet to get my long-board fix. As such, a recent discovery for me is that you can get mud guards for skateboards!

The supplier/manufacturer called Wheelshields (no longer online) is an American company and you can buy them for under 100USD (around £80 pounds at the time of writing). Interestingly, the shields are mounted on the outside of the wheel using the wheel nut to secure them.

The shields are reported as definitely working with boards that have wheels of 76 mm in diameter and under. But also wheels as large as 80 mm can also be accommodated depending on the board.

The manufacturer reports additional advantages of using their wheel shields other than just for splash protection. This includes eliminating wheel bite and increasing bearing life. A review of the wheel sheilds by 14Degrees (no longer online) claims these are a positive game changer.

Alas, the manufacturer will not get my immediate request for purchase as my wheels are 90mm in diameter. I have sent them an email to enquire if they make a solution for bigger wheels. In the mean time it's given me an idea to try and make my own guards. Watch this space :)

Tuesday 7 February 2017

Comparing top speeds (in a fair way)

What is needed is an industry standard dynamometer for electric skateboards. Ideally this would be done by a (certified) test house, and electric board manufactures would send in their boards there for testing.

Interestingly, there is a chap on the Facebook electric board Users who has very recently shown his dynamo-meter for electric skateboards (pictures below). Lets hope something like this can be adopted into the electric skateboard industry.

Sunday 5 February 2017

Testing for speed

Hooray at last! Due to a sunny period this afternoon I was able to steal some time to test my electric long-board top speed.

Readers of my recent posts will know that I have completed the re-purposing and fitting of a bike computer in order to measure distance covered and speed of my electric board. I wanted a permanent device mounted onto my board so it behaved like an odometer in a car. If I ever sold the board there would be a permanent log of the miles covered. But also the intention is that I can use the real time speed and distance display to help assess how much more distance I have available before the battery goes flat.

Previously, when initially measuring the board speed through the bike computer I had measured a top speed on the day of 11mph. I have always been curious about how accurate this was, given that the claim from Volo-E for this board is a top speed of 14mph. In the back of my mind I was questioning if I had calibrated the bike computer correctly and/or if might my weight (85 kg) was significant enough to reduce the total max speed.

The bike computer counts the number of times the wheel rotates by counting the presence of a magnet each time it passes the sensor in a period of time. I wanted to see if the speed could be measured in an alternative way to verify the bike computer results.

Well today I downloaded the first free iOS app I found (called WalkFree) to measure my top speed. This app uses GPS to give a much more accurate result then counting wheel rotations. By sampling the GPS positions and taking two of the GPS locations, the app calculates the distance covered. As with the bike computer, the speed is calculated by distance covered by the time taken (S = d /t).

Well that app recorded a top speed of 11.14 mph! I wasn't able to do exhaustive testing as there were cars interrupting my path. But the good news is both methods report the near same results and it is confirmed that my re-purposed bike computer is doing its job. The bad news is that my electric long-board is slower than I thought :(

Dang, I had a high suspicion that the only other guy I have seen electric skateboarding in my city had a better performing board than me.....

Don't believe that Vert Drop reading. That remained the same throughout the testing.

Readers of my recent posts will know that I have completed the re-purposing and fitting of a bike computer in order to measure distance covered and speed of my electric board. I wanted a permanent device mounted onto my board so it behaved like an odometer in a car. If I ever sold the board there would be a permanent log of the miles covered. But also the intention is that I can use the real time speed and distance display to help assess how much more distance I have available before the battery goes flat.

Previously, when initially measuring the board speed through the bike computer I had measured a top speed on the day of 11mph. I have always been curious about how accurate this was, given that the claim from Volo-E for this board is a top speed of 14mph. In the back of my mind I was questioning if I had calibrated the bike computer correctly and/or if might my weight (85 kg) was significant enough to reduce the total max speed.

The bike computer counts the number of times the wheel rotates by counting the presence of a magnet each time it passes the sensor in a period of time. I wanted to see if the speed could be measured in an alternative way to verify the bike computer results.

Well today I downloaded the first free iOS app I found (called WalkFree) to measure my top speed. This app uses GPS to give a much more accurate result then counting wheel rotations. By sampling the GPS positions and taking two of the GPS locations, the app calculates the distance covered. As with the bike computer, the speed is calculated by distance covered by the time taken (S = d /t).

Well that app recorded a top speed of 11.14 mph! I wasn't able to do exhaustive testing as there were cars interrupting my path. But the good news is both methods report the near same results and it is confirmed that my re-purposed bike computer is doing its job. The bad news is that my electric long-board is slower than I thought :(

Dang, I had a high suspicion that the only other guy I have seen electric skateboarding in my city had a better performing board than me.....

Don't believe that Vert Drop reading. That remained the same throughout the testing.

Wednesday 1 February 2017

Man! When is it going to stop raining!

Have been waiting a long while now in order to test the bike computer with my long-board. But so far only rain :( Hence the following little experiment (for curiosity):

Tuesday 31 January 2017

Securing the bike computer ancilliaries

The bike computer ancillary box (containing the battery, reset switch, and connections for the magnet sensor) was placed directly behind the front wheel truck. This ensured the smallest length cable possible to the bike computer.

The original road test used blue tack to hold the magnet sensor to the truck axle. The bike computer was actually supplied with cable ties to secure it to the fork of a bicycle. These cable ties are also ideal for securing the magnet sensor to the truck axle.

The original road test used blue tack to hold the magnet sensor to the truck axle. The bike computer was actually supplied with cable ties to secure it to the fork of a bicycle. These cable ties are also ideal for securing the magnet sensor to the truck axle.

Sunday 29 January 2017

Invalidating my board warranty (again)

Previously I had drilled and chiselled a recess in the board to house the bike computer. To keep this area water tight (I didn't want the lovely Canadian ply to start separating or get swollen due to water ingress), I took the nearest paint pot to hand and painted the recess area with black paint.

Now that the bike computer was ready to be mounted onto the long board, I had to drill another hole in the board in order to feed the bike computer cable through.

Not, a good looking result, but then again this area is covered by the bike computer. And here is the result:

Now that the bike computer was ready to be mounted onto the long board, I had to drill another hole in the board in order to feed the bike computer cable through.

Not, a good looking result, but then again this area is covered by the bike computer. And here is the result:

Monday 16 January 2017

Electrical repurposing of a bike computer

Regular readers of the blog will recall that I removed the back of the bike computer enclosure to reduce its thickness (I didn't want to have a chance of kicking it off). Removing the back lid meant that the battery, the wire points connecting to the magnet sensor, and the reset switch had to be removed. All these components required a home remote from the new slimmer bike computer. I had planned that the "home" comprising a small plastic enclosure would be positioned on the underside of the long board.

First off, I carefully soldered six wires to the existing connection points on the back of the bike computer PCB. Two wires (purple and brown) for the magnet sensor, two wires (blue and green) for the reset button, and two wires (black and red) for connecting to the battery.

Now, electrical connections on a skateboard have to be quite robust since even riding on normal tarmac road the board is subject to a lot of vibrations. This is where UniBond 100% power glue comes in. After doing a quick electrical test with a multimeter to confirm good solder contact for the wires and that I had not introduced any shorts, I put a big dollop of UniBond glue on the back of the PCB. I made sure that all the wires were submerged in this glue. After 24 hours the result was a layer of resin (couple of mm thick) on the back of the PCB securing all the wires.

The next step was to source an enclosure for housing the battery, reset button and magnet sensor connections.This was a generic off-the-shell small plastic box available from an electronic component supplier. Once the box was delivered I was then able to cut a piece of vero-board to fit within the box and populate it with a battery holder, reset switch and screw terminal PCB connectors.I made wire connections from the switch and battery to the terminal block connectors. I also fitted a rubber cable sleeve to the side of the box in order to reduce any strain on the bike computer cable and magnet sensor cable feeding into this box.

From the bike computer newly soldered in cable, I wired in the black and red wires for the battery, the green and blue wires for the switch. I took the existing magnet sensor cable and wired that to the brown and purple wires of the cable.

Hey presto, I had a working bike computer. Each time I waved a magnet near the magnet sensor the LCD screen showed a "cycling" graphic.Moving the magnet close and far way in quick succession resulted in the mph reading changing!

Its time to mount all on the board!

Subscribe to:

Posts (Atom)